Feeders

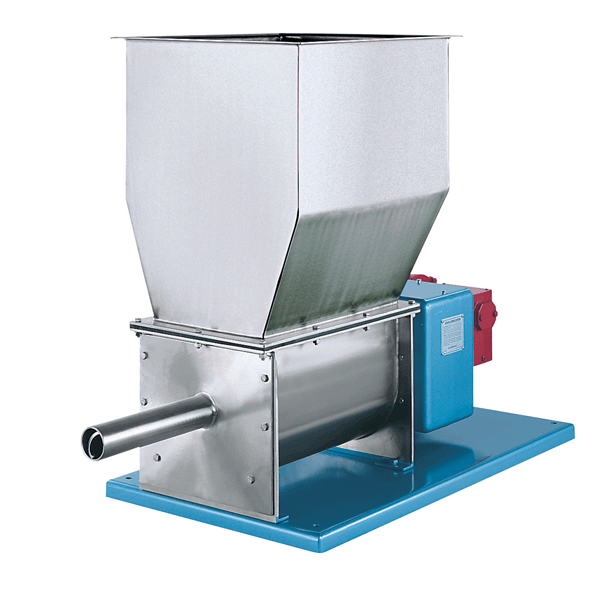

Volumetric Feeders

Volumetric Feeders meter a specific volume of product to achieve a specific rate. Typically using an auger, a volume is measured and discharged with each rotation of the auger. Ideal for feeding free flowing bulk materials such as pellets and powders. Very common and economical feeder option.

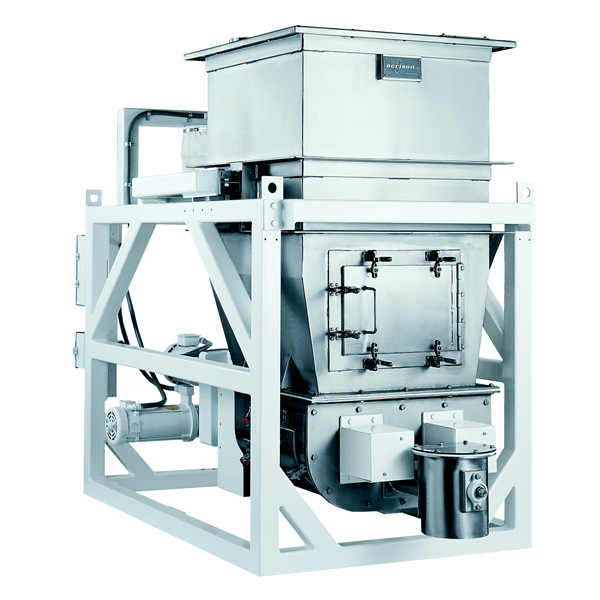

Gravimetric Feeders

Gravimetric Feeders, otherwise known as Weight-Loss or Loss-In-Weight feeders, work by discharging a specific and measurable amount of material over a specific amount of time. Highly precise and highly dependable for continuous product metering. Perfect for food processing, pharmaceutical, plastics, chemicals, water & wastewater.

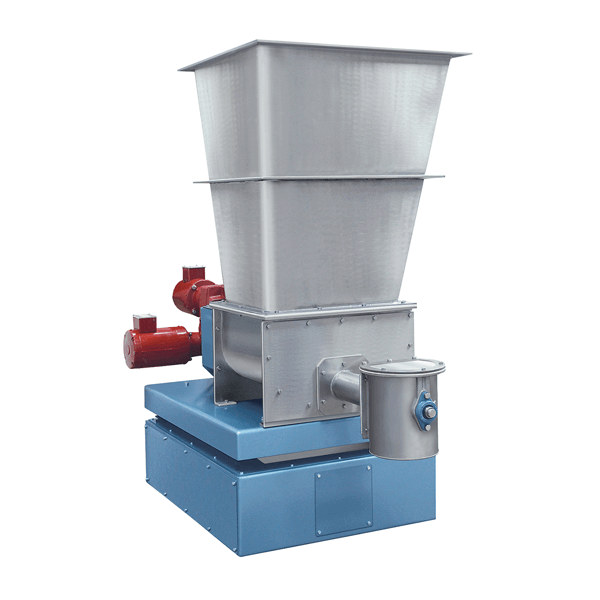

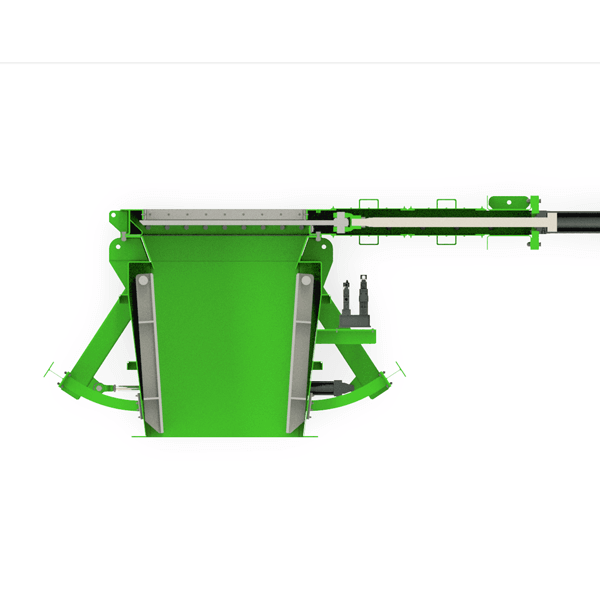

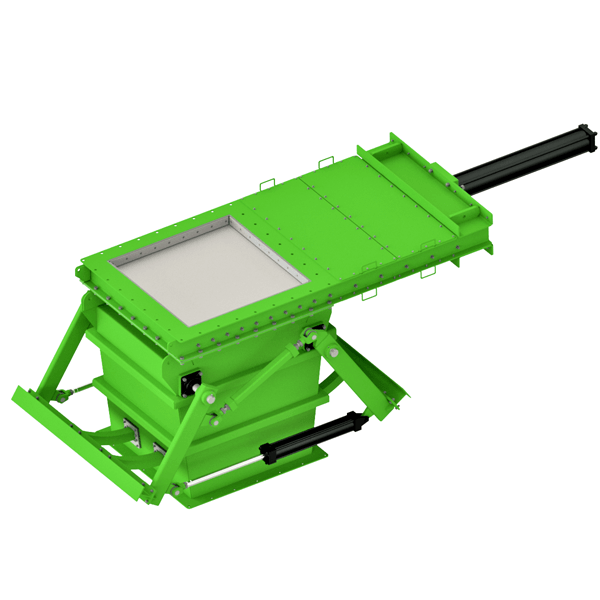

Mass Flow Feeders

Mass Flow Feeders and Rolling Blade Belt Feeders are engineered to provide exceptional accuracy. Mass Flow Feeders uniformly load the belt on center line every time, regardless of flow rate. Simple, reliable designs require little maintenance and provide more up time over the life of the system than any other feeder technology. Repeatable accuracies of <1%.

What other types of feeders do you work with?

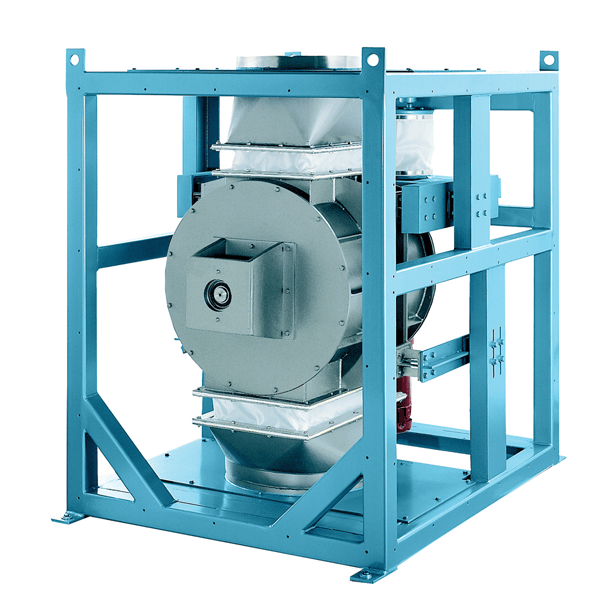

ROTARY AIRLOCKS AND ROTARY FEEDERS

Ensure accurate material loading and also minimize pressure loss throughout the system. Able to feed process materials into pneumatic conveying applications. Can regulate the flow of material from one chamber to another. Sanitary, Quick-Take-Apart, Abrasion Resistant, and Blow-Thru options available.